MATERIALS.CO.UK

Metals • Plastics • Rubbers • Polymers • Ceramics • Composites

Metals • Plastics • Rubbers • Polymers • Ceramics • Composites

Metals • Plastics • Rubbers • Polymers • Ceramics • Composites • Coatings

Coating Analysis

Examination of coatings and surface treatments including:

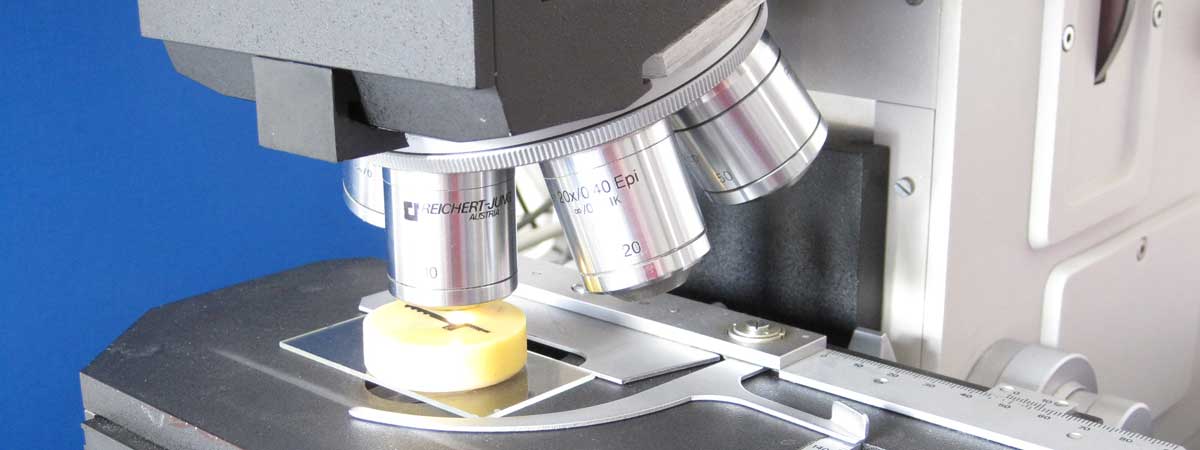

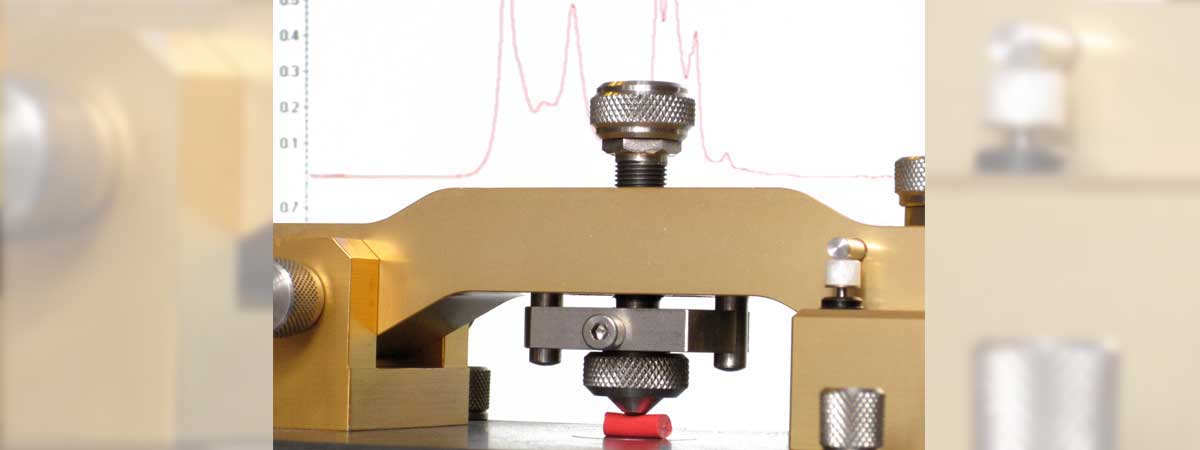

Further examination techniques used to examine coating samples include optical microscopy and Fourier transform infra-red spectroscopy to determine any polymeric components.

Other properties relevant to coating analysis are hardness and adhesion. Microhardness surveys can be used to analyse case depths and hardness of individual layers. Adhesion of coatings to metal substrates can be determined by applying and removing tape over cuts made in the film.

- Anodising

- Thermal spraying

- Paints

- Plating

- Zinc/galvanising

- Chromating

- Case hardening

- Nitriding

- Laser cladding

- Electrical contacts

- Texture

- Composition of individual layers

- Composition of constituent phases and particles within layers

- Thickness measurements

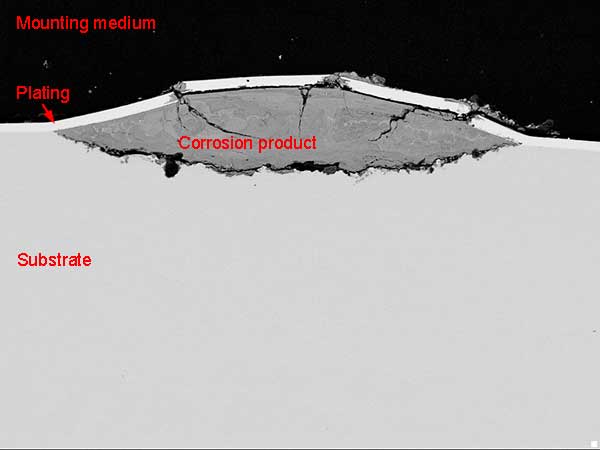

- Investigation of defects

- Delamination

- Corrosion damage

- Fretting and wear damage

- Porosity

Further examination techniques used to examine coating samples include optical microscopy and Fourier transform infra-red spectroscopy to determine any polymeric components.

Other properties relevant to coating analysis are hardness and adhesion. Microhardness surveys can be used to analyse case depths and hardness of individual layers. Adhesion of coatings to metal substrates can be determined by applying and removing tape over cuts made in the film.

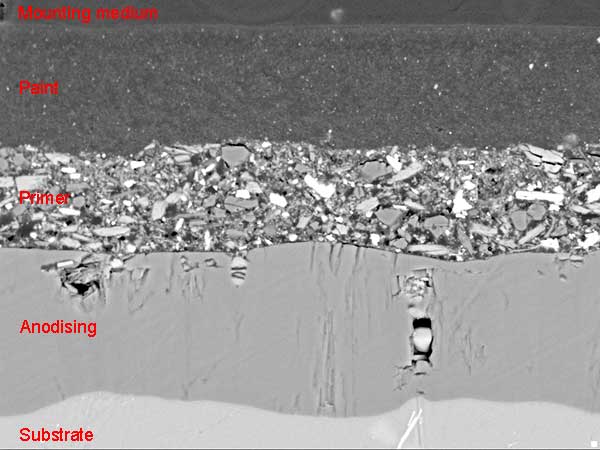

Component with anodised and paint layers

Analysis of anodised layer

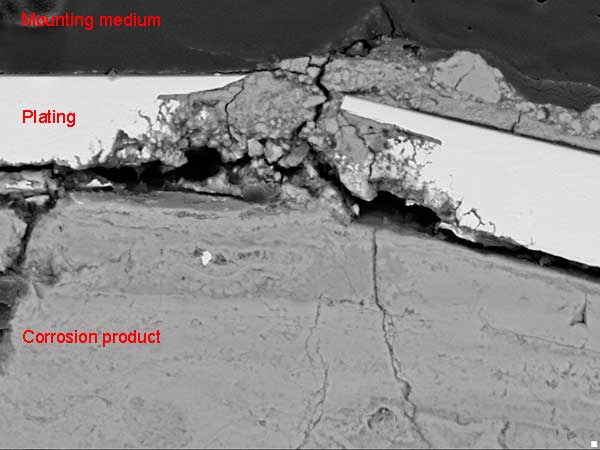

Corrosion attack of substrate beneath plating