Brinell Hardness

Description

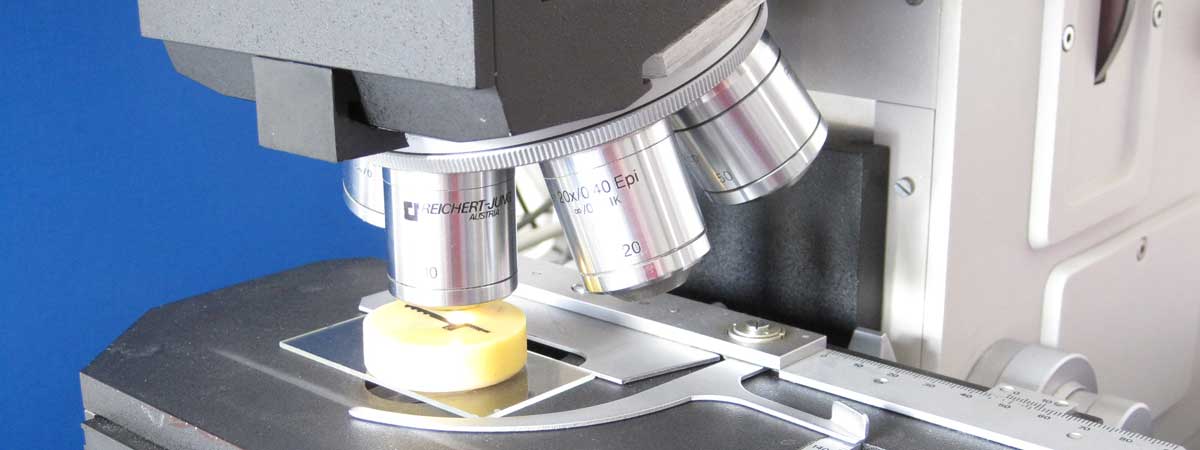

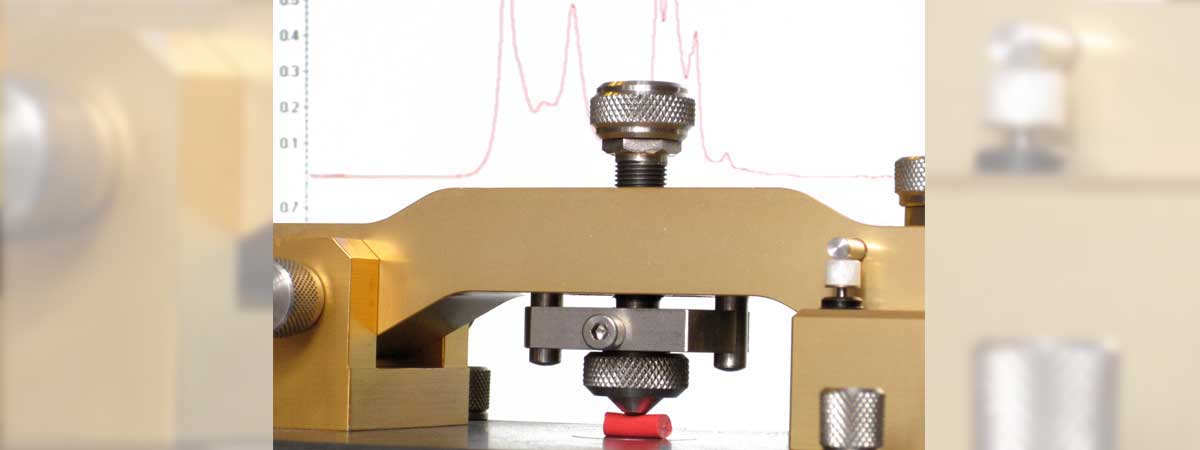

The Brinell hardness test uses a ball indenter of diameter, D, which is pressed into the surface of the test piece using a prescribed force, F. The time for the initial application of the force is 2 s to 8 s, and the test force is maintained for 10 s to 15 s. The diameter of the indentation, d, is measured after the force has been removed. The Brinell hardness number, HB, is given by:

HB = Constant × F / Surface area of indentation

![]()

Standard Brinell Scales

| Hardness scale | Ball diameter, D (mm) |

Nominal force, F (N) |

| HBW 10/3000 | 10 | 29420 |

| HBW 10/1500 | 10 | 14710 |

| HBW 10/1000 | 10 | 9807 |

| HBW 10/500 | 10 | 4903 |

| HBW 10/250 | 10 | 2452 |

| HBW 10/100 | 10 | 980.7 |

| HBW 5/750 | 5 | 7355 |

| HBW 5/250 | 5 | 2452 |

| HBW 5/125 | 5 | 1226 |

| HBW 5/62.5 | 5 | 612.9 |

| HBW 5/25 | 5 | 245.2 |

| HBW 2.5/187.5 | 2.5 | 1839 |

| HBW 2.5/62.5 | 2.5 | 612.9 |

| HBW 2.5/31.25 | 2.5 | 306.5 |

| HBW 2.5/15.625 | 2.5 | 153.2 |

| HBW 2.5/6.25 | 2.5 | 61.29 |

| HBW 1/30 | 1 | 294.2 |

| HBW 1/10 | 1 | 98.07 |

| HBW 1/5 | 1 | 49.03 |

| HBW 1/2.5 | 1 | 24.52 |

| HBW 1/1 | 1 | 9.807 |

The designation "HBW" specifies the use of a tungsten carbide ball indenter.

The designation "HBS" specifies the use of a hardened steel ball indenter but is now deleted from standards.

It should be noted that measurements of HBW and HBS on the same sample may differ in value due to differences in the tribological characteristics of the indenter-specimen interface.

Standards

| BS EN ISO 6506-1:2014, (BS 240:Part 1:1962) | Metallic materials. Brinell hardness test. Test method |

| ASTM E10-18 | Standard Test Method for Brinell Hardness of Metallic Materials |